3DUJ-553

The world’s first full-color 3D UV-curable inkjet printer

With the Mimaki 3DUJ-553 UV LED printing solution we introduced a brand new approach to 3D printing. This is the world’s first 3D printer with over 10 million colours, enabling the production of 3D objects, eliminating the time-consuming finishing and the risk of damaging small detailed parts.

|

|

|

|

|

|

|

|

|

|

|

Applications

Prototypes, tools (making industry), architecture models, offshore & ship presentation models, toys, 3D art, 3D signing, accessories and more.

Specifications of 3DUJ-553

| Item | 3DUJ-553 | |

| Modelling method | UV curable inkjet | |

| Available colour number | Full colour/More than 10 million different colours | |

| Print head | On-demand piezoelectric print head (8 heads inline) | |

| Ink | Type | Modelling ink MH-100(C,M,Y,K, White, Clear) Support material ink SW-100 |

| Colour | C,M,Y,K, White, Clear, Support material | |

| Tank volume | C,M,Y,K:3L White, Clear, Support material 5L | |

| Supply style | Pump C,M,Y,K:1L bottle White, Clear, Support material 4.8L bottle | |

| Available modelling area (W×D×H) | 508×508×305mm (20x20x12in) | |

| Minimum layer pitch | 20㎛ | |

| Modelling time (Modelling 100×100×100mm(W×D×H) object) | High speed mode: 14.4 hours 600x300x600dpi (42㎛) Standard mode: 17.0 hours 600x300x800dpi (32 ㎛) High definition mode: 25.7 hours 600x300x1270dpi (22 ㎛) | |

| 3D data format | STL, OBJ, VRML, PLY, 3MF | |

| Software (Standard accessories) | Layout software (Mimaki 3D Link) | |

| Interface | Ethernet 1000BASE-TX | |

| Power | Single phase AC 100-120V/220-240V±10% 50/60Hz±1Hz | |

| Safety standard | VCCI Class A/FCC Class A/ Compliant with UL60950, ETL / CE Marking (EMC, Low Voltage Directive)/CB Report/ RoHS/REACH | |

| Outside dimensions (W×D×H) | 2.250×1.500×1.550 mm (88,6×59,1×61,0 inch) | |

| Weight | 600 kg (1.322,8 lb) (mounted ink weight incl.) | |

* Specifications, designs and dimensions stated in this list may be subject to change without notice due to technical improvement etc.

Supplies for 3DUJ-553

| Supplies | Type | Quantity |

| Ink | MH-100 (CMKY) | 1L bottle |

| MH-100 White | 4,8L bottle | |

| MH-100 Clear | ||

| Support material | SW-100 |

Features of 3DUJ-553

More than 10 million colours

With its UV LED curing method, the 3DUJ-553 is able to print objects layer by layer applying UV ink using CMYK, white and clear at a layer thickness of 22, 32 or 42 microns, producing a finished object of exquisite quality. UV LED curing also applies minimal heat to the object. The printer exhibits fast start-up times and minimal power usage, reducing the overall running costs.

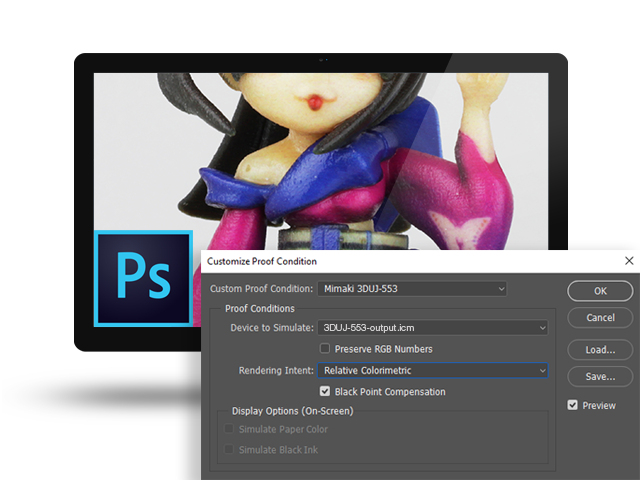

Colour profiles

The 3DUJ-553 is the world’s first 3D printer to take advantage of colour profiles. This means not only accurate colour from the printer but also allows the development of proofing profiles for accurate viewing of colour on a calibrated monitor. This ensures accurate colour simulation before printing even begins, saving time and reducing waste.

By implementing a color proofing profile created by [MPM3] (option) to Adobe Photoshop, the colour can be simulated and checked on your monitor. The colours of the final printed object will be realistic and will approach the colours that were displayed on your monitor. By using proofing profiles, reduction of colour adjusting is a huge benefit saving your precious time. Just print your coloured object in one “shot”.

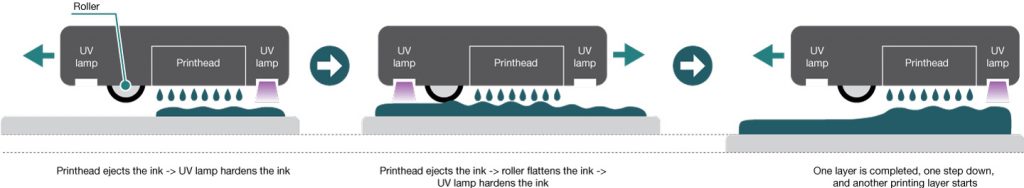

UV Inkjet method

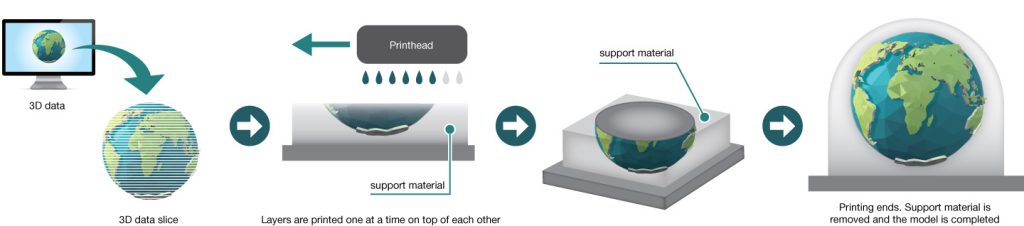

UV curable ink is hardened with UV light. Mimaki’s technology involves laying down successive layers of UV curable ink, one on top of the other, until the desired model is completed.

Lamination and colour fixing

3D data is sliced and printing starts simultaneously for ink and support material until the model is completed.

Add translucency with clear ink

Using clear ink adds an additional effect to 3D printed objects, especially if the object is illuminated. The combination of clear and CMYK inks opens the door to increased designer creativity.

Excellent post-process performance

The inks used by the 3DUJ-553 contain an acrylic resin that produces hardness equivalent to ABS plastic. This means that overcoating, drilling and attachment of screws can be accomplished without damaging the object. It also adds superior weather resistance, surface smoothness and strength to the object.

Water-soluble support material

The 3DUJ-553 uses a water-soluble support structure which can be washed away with water. Removal of the support material using water, enables highly detailed models to be created without damaging the objects during this removal process.

Stable operation

Continuous ink flow is made possible by using an ink sub-tank installed in the print head. This prevents pigment deposits, air bubbles and ensures ink is emitted correctly. Additionally, this prevents missing nozzles and maintains a stable print environment and keeps the up-time of the printer extremely high.

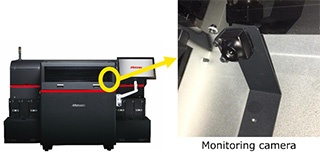

Camera for monitoring of modelling status

The 3DUJ-553 has a monitoring camera that enables users to remotely observe the modelling status.

Here you will find some Frequently Asked Questions about the 3DUJ-553.

Please contact us through our contact form (above request info button) if you would like to receive more information about our 3D printer.

Specifications of Mimaki 3D printer

What is the printing method?

UV curable inkjet printing. The printed layers of UV curable acrylic resin inks create an object.

What material is used to create an object?

Mimaki genuine acrylic resin ink.

Is the support material necessary for creating an object?

Yes, Mimaki 3D printer uses the support material.

Is it possible to reuse the support material?

No, it is not possible.

What is the layering pitch?

High speed mode: 42 μm, Standard mode: 32 μm, High definition mode: 20 μm

Is the ink reusable when the modeling is failed?

No, it is not reusable.

What is the expiry of ink?

It is about one year after manufacturing.

Is it available to execute multiple data of modeling?

It is available to have modeling by locating the multiple data by layout software.

Software

Is the software developed by Mimaki?

Layout software is developed by Mimaki.

Layout software: [Mimaki 3D Link]

Is [Mimaki 3D Link] an optional software?

No, it is bundled to the printer.

What is the availabe 3D data format?

It is STL, OBJ, VRML, PLY and 3MF.

Is it possible to create a 3D data by [Mimaki 3D Link]?

No, it is not possible.

3D model

What is the available size of modeling?

The available modeling area is X=508 mm (20 in), Y=508 mm (20 in) and Z=305 mm (12 in).

As modeling is including the support material area, the modeling size will be varied depending on its shape.

Is it possible to make an object hollow?

Yes it is possible depending on the data.

How much weight will it be while modeling with the size of 500 x 500 x 300mm?

When the modeling is made in cuboid, it will weigh 80 kg approx.