UJF-7151plus

Next-generation direct-to-object production flatbed LED UV printer

Capitalising on its peerless heritage in compact UV LED direct- to-object print technology, the UJF-7151plus reaffirms Mimaki’s market dominance in this rapidly developing sector. Geared to on-demand printing of the very highest quality at industrial production levels of output, UJF-7151 plus utilises state-of-the-art technology to deliver a powerful and reliable digital alternative to traditional screen print operations.

|

|

|

|

|

|

|

|

Create…

Promotional items, personalised giftware, bespoke products, control panels, pens, packaging, small-medium format rigid signage, instrumentation & gauge faces, custom components, branded electronic device cases and covers and much more…

Specifications of UJF-7151plus

| Print head | On-demand piezo head (6 staggered printheads ) |

| Maximum print area | 710 × 510mm |

| Printing resolutions | 1,200dpi |

| Ink type | LH-100 (C, M, Y, K, W, Cl) |

| PR-200 (Primer) | |

| Ink capacity | 1L bottle |

| Media size | 710 × 510mm or smaller |

| Media thickness | |

| Media weight | 10kg or less |

| UV device | UV LED |

| Interface | USB 2.0 Hi-speed / Ethernet 1000BASE-T |

| Power consumption | 1.3 kW |

| Dimensions (w x d x h) | <2,198 × 1,572 ×1,273mm |

| Weight | <317kg (Base stand weight is included) |

UJF-7151plus inks: LH-100 & LUS-120 are GREENGUARD Gold certified.

Features of UJF-7151plus

High quality industrial construction

Delivers precision output

In order to reduce printer unit vibration, the print table moves during printing instead of the Y-bar. Two ball screws are installed on both sides of the table to assist with its movement. In addition, four motor-driven legs are added beneath the table to maintain its horizontal position when the table is lifted or lowered, resulting in a more precise droplet placement and higher quality print output.

Uninterrupted printing features

Maintain high productivity levels

In the event of a nozzle malfunction not being repairable by the use of the maintenance function, printing can continue by the use of another nozzle, without any loss of productivity or a reduction in image quality.

Ink Circulation System

Located in the print head reduces ink settling and provides stable ink jetting. In addition, the system removes air bubbles, which plug the nozzle. Nozzle-cleaning frequency is thereby reduced, resulting in a more cost-effective and stable print output.

MAPS4 Advanced Pass System

Mimaki’s unique anti-banding feature, MAPS4 is a more advanced version of MAPS3. To prevent banding, swath boundaries are overprinted and boundaries prone to banding are printed with fewer ink droplets.

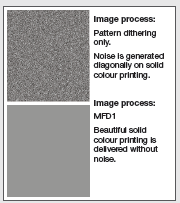

MFD1—Mimaki Fine Diffusion 1

Dithering is an image processing technique, which transforms image data for inkjet printing. Pattern and error-diffusion dithering may, however, generate particular image noise resulting in uneven colour printing or tone jumps, even on a high-performance printing unit.

New RasterLink 6 software*, incorporates patented* image-processing MFD1, which reduces noise due to dithering through hybrid processing of pattern- and error-diffusion dithering, thereby enhancing print quality.

* MFD1 is available for Version 4.0 and higher

* Patent number: 5230816

Environmentally-friendly Technology

Environmentally-friendly Technology

- UV LEDs have longer life and consume less energy than conventional UV lamps

- Less transfer waste and no wasted inventory by printing on-demand, direct-to-substrate

- No noticeable odour and no excessive noise

UJF-7151plus inks: LH-100 & LUS-120 are GREENGUARD Gold certified.