CG-FXII Plus

New world standard of multi-cutting plotter

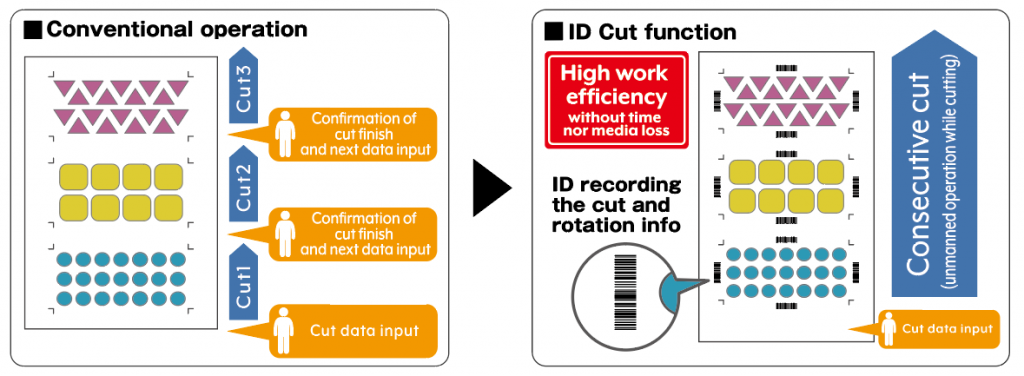

The CG-FXII Plus introduces its new ID Cut function to vastly improve work efficiency. In collaboration with the JV300-160 Plus, continuous cutting operations can be performed automatically for small-quantity and multi-product orders of stickers and labels. It enables an entire operation to be completed in a single specification of data so that operators can proceed with other jobs simultaneously.

|

|

|

|

|

|

|

|

|

Create…

Clothing, logos, stickers, labels, decals, graphics and signage

Substrates

(Coloured) vinyl, transparent PET, (transfer) paper, flock, rubber.

Specifications of CG-FXIIplus

| Item | CG-75FXII Plus | CG-130FXII Plus | CG-160FXII Plus | |

| Acceptable sheet size | Width | 90 – 1,040mm (3.54 – 40.9”) | 90 – 1,580mm (3.54 – 62.0”) | 90 – 1,880mm (3.54 – 74.0”) |

| Roll weight | 18kg (39.7lb) or less | 22kg (48.5lb) or less | ||

| Roll dia | 200mm (7.87”) or less | |||

| Effective cutting area※1 | 760mm x 51m (29.9” x 167’) | 1,300mm x 51m (51.2” x 167’) | 1,600mm x 51m (63.0” x 167’) | |

| Max. auto cutting area※2 | 870mm (34.3”) | 1,425mm (56.1”) | 1,720mm (67.7”) | |

| Max. cutting speed | 100cm/s | |||

| Max. moving speed | 140cm/s (In a 45° direction and in a pen-up state) | |||

| Adjustable speed range (cutting /plotting)※3 | 1 ‒ 10 cm/s (1 cm/s step), 10 – 50 cm/s (5 cm/s step) 50 – 100 cm/s (10 cm/s step) | |||

| Mechanical resolution | 5 μm (0.0002”) | |||

| Command resolution | 25 μm, 10 μm (MGL-IIc), 100 μm, 50 μm (MGL-Ic1) | |||

| Repeatability | ±0.2mm (0.0079”) | |||

| Excluding shrinkage/expansion caused by the film temperature | ||||

| Accuracy assurance range | 760mm × 10m (29.9” x 0.39”) | 1,300mm × 10m (51.2” x 0.39”) | 1,600mm × 10m (63.0” x 0.39”) | |

| Depending on the specified film and cutting conditions | ||||

| Max. pressure | 500g | |||

| Pressure setting | Cutter | 10 – 20 g (2 g step), 20 – 100 g (5 g step), 100 – 500 g (10 g step) | ||

| Pin | 10 – 20 g (2 g step), 20 – 100 g (5 g step), 100 – 500 g (10 g step) | |||

| Pen | 10 – 20 g (2 g step), 20 – 100 g (5 g step), 100 – 150 g (10 g step) | |||

| Acceptable cutting sheet※4s | Vinyl up to 0.25mm (0.01”) thickness, Fluorescent sheet, Reflective sheet | |||

| Acceptable sheet for pouncing※5 | Paper thickness 0.06 – 0.13 mm (0.0024″ – 0.005″) | |||

| Applicable tools※6 | Cutter, Water based ball-point pen, Oil based ball-point | |||

| Type of command | MGL-IIc/Ic1 | |||

| Interface | RS-232C/USB | |||

| Receiver buffer size | 30Mb standard (20Mb when in sorting) | |||

| Operation environment | Temperature : 5 – 35 degrees Humidity : 35 – 75% (Rh) Non-condensationAC100V – 240V 1A 50/60Hz | |||

| Power | AC100V – 240V 1A 50/60Hz | |||

| Power consumption | 100W or less | |||

| Dimensions (W×D×H) | 1,285 x 700 x 1,217mm (50.5” x 27.5” x 47.9”) | 1,825 x 700 x 1,217mm (71.8” x 27.5” x 47.9”) | 2,128 x 700 x 1,217mm (83.6” x 27.5” x 47.9”) | |

| Weight | 47kg (104lb) | 62kg (137lb) | 70kg (154lb) | |

*1: Maximum sheet feeding length differs depending on the software.

*2: Sheet width to cut off from the roll.

*3: Restricted sheet width.

*4: Provided that the blade specific to fluorescent type vinyl (SPB-0007) and the blade specific to reflective sheet (SPB-0006) are used.

*5: Pouncing tool intended specifically for pouncing shall be used.

*6: The goods on the market are φ8~φ9 mm pen. Accuracy and image quality are not guaranteed.

Features of CG-FXIIplus

The CG-FXII Plus introduces its new ID Cut function to vastly improve work efficiency. In collaboration with the JV300-160 Plus, continuous cutting operations can be performed automatically for small-quantity and multi-product orders of stickers and labels. It enables an entire operation to be completed in a single specification of data so that operators can proceed with other jobs simultaneously.

New ID Cut Function

ID Cut for continuous and automated cutting operation

- A new “ID Cut function” has been adopted, enabling continuous cutting operation to be performed automatically

- The “ID Cut function” automatically scans printed-out register marks with ID, then reads and cuts the cut data. While operators scanned register marks and specified cut data for each cutting job in the past, implementation of the new “ID Cut” function now makes possible the ability to perform unmanned and continuous cutting operations, with operators free to proceed with another operation simultaneously while the machine is performing the cutting operation.

Use ID Cut in combination with JV300Plus

- JV300 Plus is capable of using ID Cut by means of the CG-FXII Plus after printing out data provided with ID

Key features

High speed continuous crop mark detection using optical sensor

- An optical sensor enables the automatic consecutive detection of crop marks throughout the nested image which the Inkjet printer prints, in combination with the automatic adjustment function to obtain precise contour cutting

FineCut9

- Crop mark position data, which are received by command from standard attached plugin software “FineCut”, enables quick movement between crop marks, enabling stress-reduced cutting

By continuously detecting a maximum of 4 points, nested images in both X axis and Y axis can be cut, aligning each image automatically.

Accurate media feeding ensures precise contour cutting over longer-length prints

- Necessary media length is fed in advance to reduce tension during cutting. This function increases the precision of long-length print media cutting

“HALF CUT” mechanism, a proprietary technology of Mimaki

- With the original half cut function, the backing sheet can be cut leaving a little bit of half cut connecting points,which can be easily detached when necessary.Various media without backing sheets can be also cut.

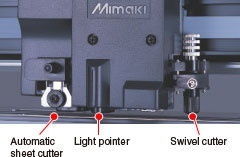

Engineered Head Unit

- The media is automatically cut with standard sheet cutters

Other features

- Selectable clamp pressure with high and low settings ensure accurate cutting of various media

- Selectable three jog speeds ensure proper and easy positioning of the head to the point

- Over-cut function makes the starting and ending points overlapped, which eliminates the uncut portion of the media

- Media can be loaded from the back or front

- Up to 6-roll media can be set at a time (1 set standard)

- Plug-in cutting software for CorelDRAW and Illustrator is included

- A special adaptor to use commercially available pens and a USB interface are included